With over 15 years of proven expertise, Cosmo Hydraulic Industries stands as a trusted Indian manufacturer and supplier of high-precision hydraulic and pneumatic fittings and components for mission-critical industrial applications.

We are established suppliers to Indian Railways and serve leading sectors including Oil & Gas, Steel, Defence, Infrastructure, and Heavy Engineering. Our products are engineered to deliver consistent performance under extreme pressure and demanding operating conditions.

Guided by the Make in India initiative, we emphasize indigenous manufacturing, stringent quality control, and globally competitive standards. We welcome clients and partners to approach us for reliable, customized hydraulic and pneumatic solutions tailored to their specific requirements.

We first focus on where and how the product will be used. Pressure conditions, environment, safety factors, and installation constraints are carefully studied before any manufacturing decision is taken. This approach helps us design solutions that work reliably, not just theoretically.

Once requirements are clear, our team finalizes design feasibility, material grades, and machining routes. Every process is planned to balance strength, precision, and long-term durability, ensuring repeatable quality across batches.

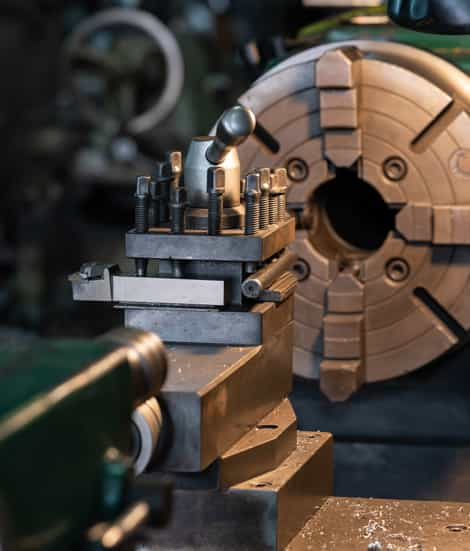

Manufacturing is carried out using CNC and precision machining practices under strict supervision. Each component is produced with close attention to tolerances, surface finish, and thread accuracy, which are critical for leak-free performance.

Instead of relying only on measurements, we focus on functional reliability. Products are inspected and tested to confirm fitment, pressure handling, and dimensional integrity, ensuring they perform exactly as intended in the field.

We understand that no two customers are the same. That’s why we support custom designs, OEM development, and flexible batch sizes, while maintaining consistent quality and dependable delivery schedules.